Rotogravure or Gravure Printing

Gravure printing gives you high-quality, sharp imagery at high speeds and is ideal for both short and long runs, or repeating runs. AMGRAPH offers a water-based, solvent-free ink option, avoiding harmful effects of solvents in other traditional inks.

Gravure printing gives you high-quality, sharp imagery at high speeds and is ideal for both short and long runs, or repeating runs. AMGRAPH offers a water-based, solvent-free ink option, avoiding harmful effects of solvents in other traditional inks.

Our newest state-of-the-art equipment reduces both time and labor due to the high efficiency of changeovers, giving you the benefit of greater cost savings. The new press also allows for the use of lightweight gravure sleeves rather than heavy steel cylinders, another cost savings for you.

Rotogravure printing gives you:

- Fewer process variables, size limitations and non-print areas

- Superior image depth and resolution

- Exceptional color reproduction, brilliance, and saturation

- Greater efficiencies for shorter print runs than traditional rotogravure

- Consistent product line results for short, medium, and long runs

As the first to offer this new printing technology in North America, AMGRAPH continues to excel in its sustainable flexible packaging. Call us today for any print quantity you need, and see how efficient rotogravure is for your high-end packaging needs.

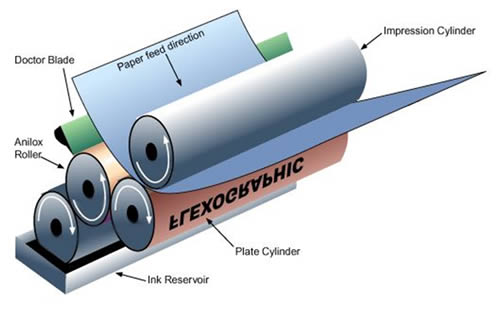

Flexography

Based on the time-tested letterpress, flexography is a modern version of traditional printing that can be used on virtually any type of substrate. It is ideal for line color in medium to long runs.

Based on the time-tested letterpress, flexography is a modern version of traditional printing that can be used on virtually any type of substrate. It is ideal for line color in medium to long runs.

AMGRAPH offers a water-based, solvent-free ink option as part of our commitment to sustainable flexible packaging processes. We’ll help you determine the right printing process for your flexible packaging product, using the most environmentally friendly methods available for your packaging needs.